Monitor Manufacturing

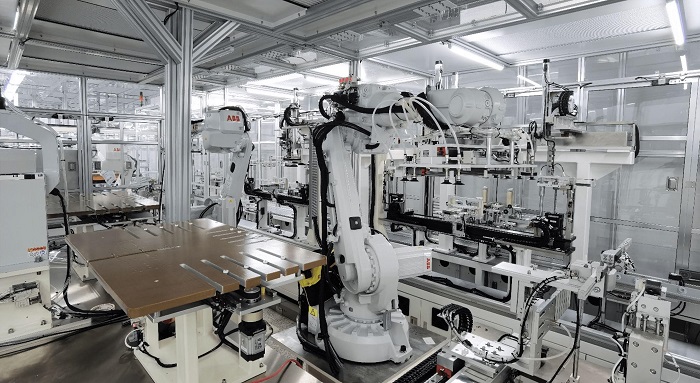

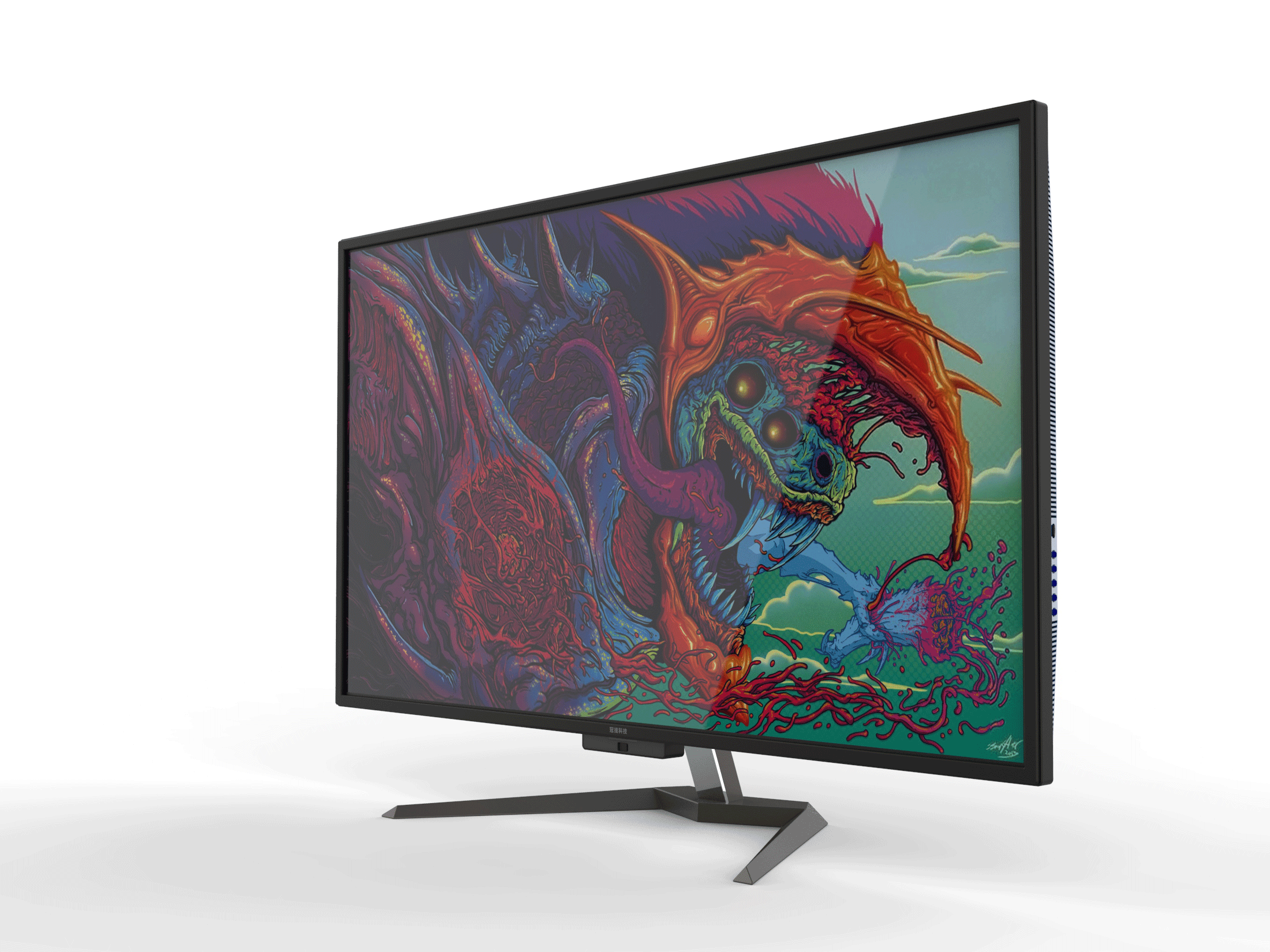

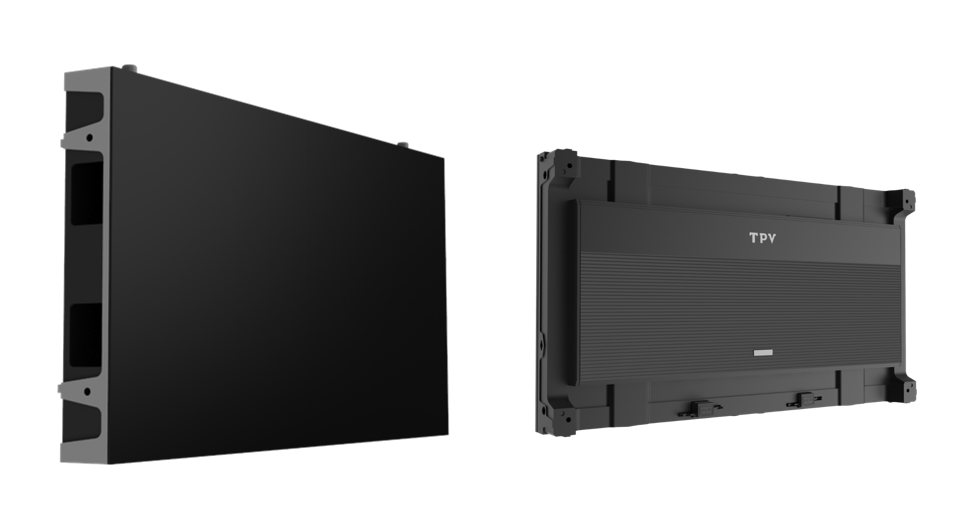

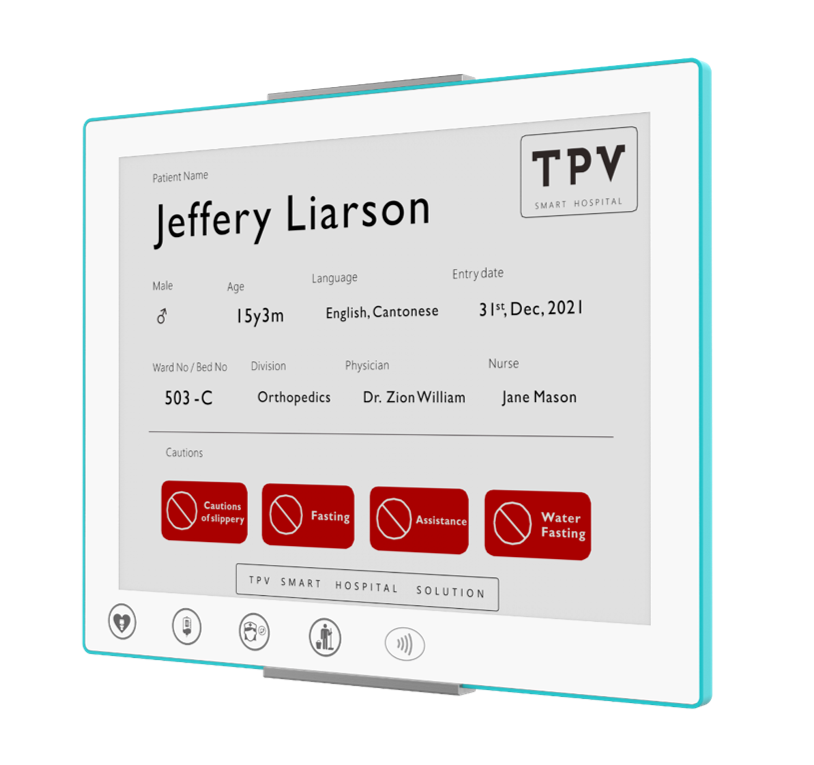

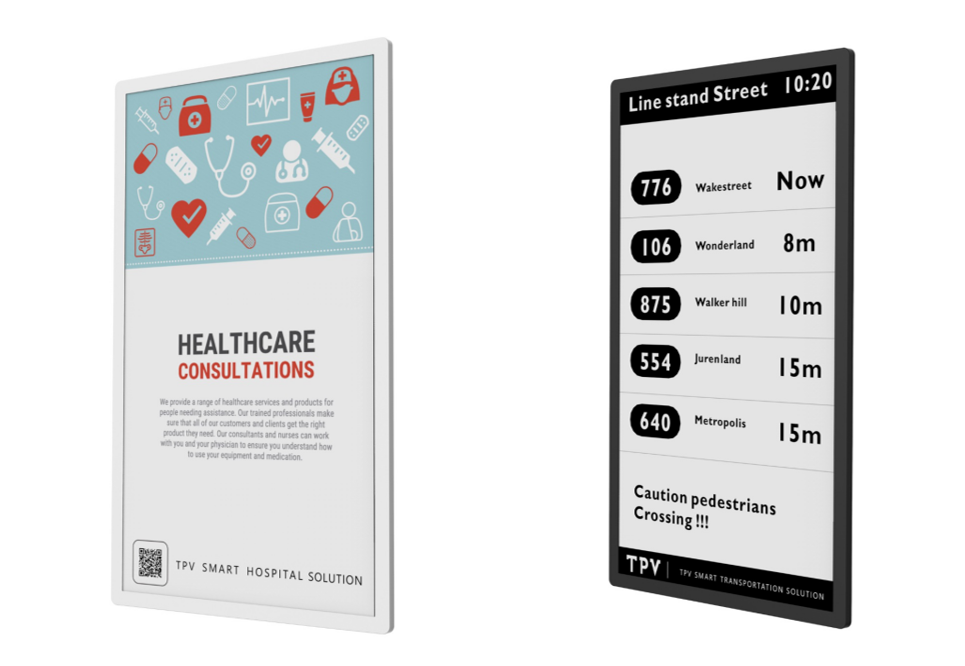

TPV provides Original Design Manufacturing (ODM) service for a wide range of high-end and professional displays including gaming, graphic design, medical and commercial displays combined with intelligent solutions.

Our experienced design teams have been working closely with many of the world's leading brands, providing competitive display solutions that include products incorporating both aesthetic design and high quality as well as providing the service to efficiently manufactured the products. Our ability to customise our display solutions to meet the needs of customers from different sectors with varying business models makes us the ideal choice for ODM partner.